Welding technology of aluminum case for flight case:

(1) Choosing welding wire Generally, 301 pure aluminum welding wire and 311 aluminum silicon welding wire are used.

(2) Select welding method and parameters flight case flight case

It is generally carried out by the left welding method, and the welding torch and the workpiece form an angle of 60°. When the welding thickness is more than 15mm, the right welding method is used, and the welding torch and the workpiece form an angle of 90°.

(3) Preparation before welding

Use chemical or mechanical methods to strictly clean the surface oxide film on both sides of the weld groove. Mechanical cleaning can use wind or electric milling cutters, scrapers, files and other tools. For thinner oxide films, 0.25mm copper wire brush can also be used to remove oxide films. Welding is performed immediately after cleaning. If it is left for more than 4 hours, it should be cleaned again.

(4) Features of aluminum and aluminum alloy materials in aluminum boxes

Aluminum is a silver-white light metal with good plasticity, high electrical and thermal conductivity, and also has the ability to resist oxidation and corrosion. Aluminum is easily oxidized to produce aluminum oxide film, which is easy to produce inclusions in the weld, thereby destroying the continuity and uniformity of the metal, and reducing its mechanical properties and corrosion resistance.

(5) Difficulties in welding aluminum and aluminum alloy materials in aluminum boxes

Very easy to oxidize. In the air, aluminum is easily combined with oxidation to form a dense aluminum oxide film (thickness of about 0.1-0.2μm), with a high melting point (about 2050°C), far exceeding the melting point of aluminum and aluminum alloys (about 600°C) . The density of aluminum oxide is 3.95-4.10g/cm3, which is about 1.4 times that of aluminum. The surface of aluminum oxide film is easy to absorb moisture. During welding, it hinders the fusion of basic metals, and it is easy to form pores, slag inclusions, unfused and other defects. Cause the weld performance to decline.

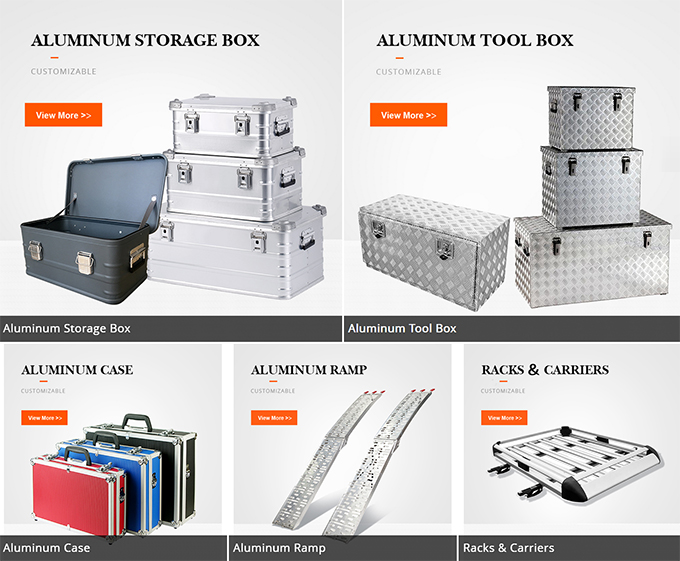

KASSICO, a leading aluminum products factory in Ningbo, China, Have 22 years' production experience in manufacturing custom aluminum storage boxes, truck tool boxes, aluminum tool case, aluminum ramp, car racks and carriers for outdoors, camping, overlanding, military, medical etc.

We supply full custom service, including developing OEM & ODM projects. Our company owns 15000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging.