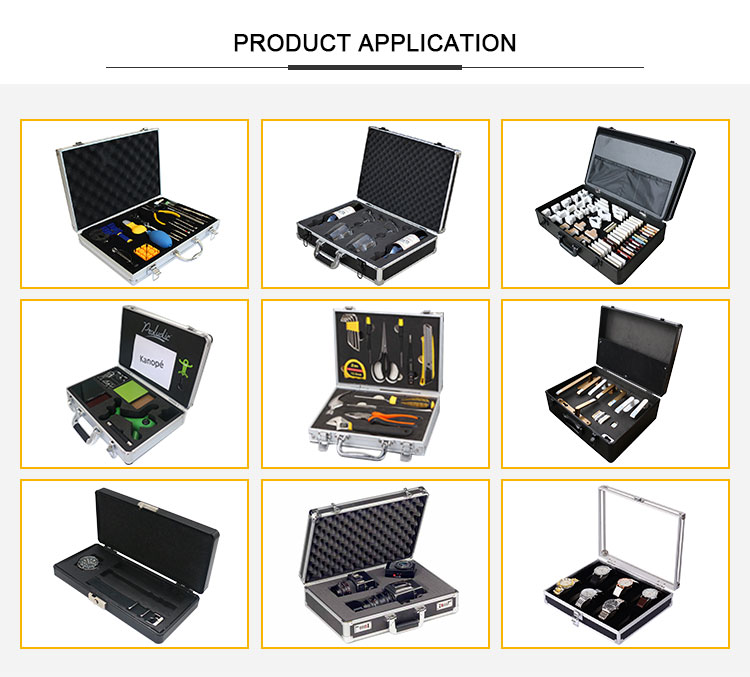

The aluminum alloy case is mainly made of aluminum alloy. Because of its special material, its performance is better than other case materials. It is generally used to transport and protect precision instruments. The aluminum alloy case is composed of four main parts: aluminum alloy frame, surface plate, lining plate and hardware. The quality of the aluminum alloy case depends mainly on the quality of these parts. So, what are the requirements for each part of the aluminum alloy case? How to judge the overall quality of the aluminum alloy case from the advantages and disadvantages of these components?

1、 Aluminum alloy frame

As the support frame of the aluminum alloy case, the firmness of the aluminum alloy frame has a direct impact on the aluminum alloy flight case. Aluminum alloy profiles are mainly prepared with aluminum, magnesium and silicon as the main elements. Each element has a certain range of content. The price of magnesium is high and low. In order to reduce costs, some manufacturers reduce the amount of magnesium to less allowable content. Some even worse, the content of magnesium is lower than the allowable lower content. Other manufacturers add waste wires and waste pots and pans to the alloy, which is basically not alloy, resulting in low mechanical strength of aluminum profiles, which can be easily bent with two hands. When aluminum cases, aluminum alloy cases and flight cases are used as transport packages or terminal packages, they must be strong.

2、 Surface plate

Aluminum case, aluminum alloy case and flight case are generally customized with aluminum plate, fireproof plate or BS plate as the surface plate. In addition to increasing the firmness of the aluminum case, the surface plate must also be attractive. Now there is a new material of imitation aluminum plate in the market. It is almost indistinguishable from the aluminum plate on the surface. The imitation aluminum plate and the aluminum plate are only similar in shape, but the price is very different. It cannot be comparable with the aluminum plate in flatness, cracking and self-cleaning function.

3、 Lining plate

The lining plates of aluminum cases, aluminum alloy cases and flight cases are mainly density plates or plywood of various thicknesses. The state has clear environmental protection standards for some boards such as density boards and plywood. At present, the environmental protection requirements of the density boards produced by most manufacturers are not up to standard, and the large amount of adhesives used makes the formaldehyde content in the boards quite high, which is harmful to the human body.

4、 Hardware

Hardware accounts for a small proportion in aluminum cases, aluminum alloy cases and flight cases, but it is undoubtedly one of its important components for aluminum cases, aluminum alloy cases and flight cases. The hardware sold in the market includes zinc plating and chromium plating. The price of zinc plating hardware is low, the service time is short, and the corrosion resistance is poor. It is not as good as chrome plating hardware. The surface of chrome plated hardware is as bright as steel. It is used in aluminum casees, aluminum alloy casees and flight casees to increase the grade of the casees and prolong the service life of the aluminum cases.

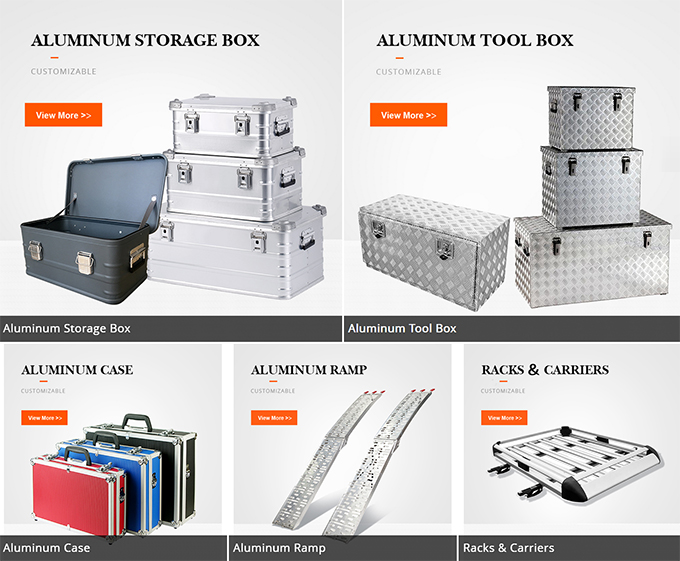

KASSICO, a leading aluminum products factory in Ningbo, China, Have 22 years' production experience in manufacturing custom aluminum storage boxes, truck tool boxes, aluminum tool case, aluminum ramp, car racks and carriers for outdoors, camping, overlanding, military, medical etc.

We supply full custom service, including developing OEM & ODM projects. Our company owns 15000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging.