Lining is an indispensable accessory for aluminum boxes, and its production process is also more complicated. The production and processing process is mainly divided into five main steps: typesetting, plate making, mold opening, material, and processing. The specific details of the production process are very important. Among them, the three processes of plate making, mold opening, and processing are important in the production process, which determine the quality of the lining produced.

Aluminum box lining Its function is mainly to protect the contents in the aluminum box and prevent damage caused by extrusion, collision, etc. Nowadays, the demand for inner lining is increasing, and customers are more and more recognized for its fixed role. It is also very convenient for aluminum box manufacturers to customize the EVA lining. After determining the internal shape of the aluminum alloy box, typesetting, milling machine processing, simple bonding, and cleaning are completed to complete a lining product. Powerful aluminum box processing enterprises attach great importance to the research, development and production of such aluminum box linings, and have made great progress in technology.

Therefore, when users choose an aluminum box, in addition to the aluminum alloy profile used in the box, they should also pay attention to the quality of accessories such as lining, which is related to the overall performance of the aluminum box.

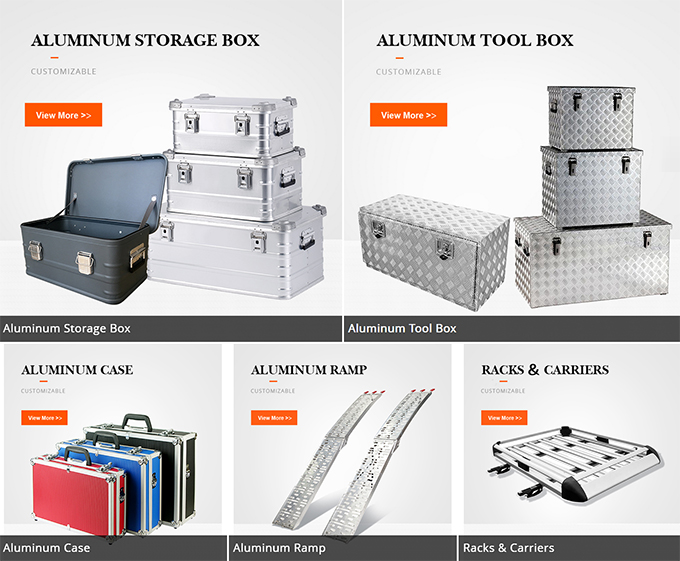

KASSICO, a leading aluminum products factory in Ningbo, China, Have 22 years' production experience in manufacturing custom aluminum storage boxes, truck tool boxes, aluminum tool case, aluminum ramp, car racks and carriers for outdoors, camping, overlanding, military, medical etc.

We supply full custom service, including developing OEM & ODM projects. Our company owns 15000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging.