Aluminum case, which is made of high-quality aluminum alloy profiles, has the characteristics of solid structure, beautiful appearance and convenient use. It is widely used in beauty salons, tool combinations, jewelry watches, stages, instruments, meters, electronics, communications, automation, sensors, smart cards, industrial control, precision machinery and other industries. It is an ideal box for high-end instruments and meters.

Classification of aluminum alloy case

Aluminum tool case

The surface material of the tool case is made of aluminum sheet or imported ABS or PVS, and its skeleton is specially developed aluminum profile. After coating, it is wear-resistant and anti-oxidation, and looks generous and temperament. Different colors can be selected on the surface of the case, so that the fabric has variability. The panel has the characteristics of wear-resistant and hard to penetrate. The lining material of the case adopts the best EVA and composite resilience solid in China. It has the characteristics of light weight, wear resistance, oxidation resistance, shock resistance, moisture resistance and so on.

Instrument case

The surface of the Instrument case is made of metal aluminum sheet or flame-retardant ABS material and aluminum frame structure, and the interior is made of shockproof material, which plays a shock absorption role and can effectively protect the products from damage. Our products have solid and beautiful corner packaging, and can be installed with rubber wheels or universal wheels to meet the needs of different occasions. When leaving the factory, our products have anti pressure, anti vibration and anti-wear outer packaging. And can be customized according to the specifications required by customers, with a variety of colors for customers to choose.

Flight case

Detailed description of Flight case: PBS flame retardant material is used on the surface of LED Flight case, which has the functions of fire prevention, water resistance, acid and alkali resistance. PBS material is a patented product of our company, and this material has the characteristics of anti-collision, strong extensibility and so on. The box wall adopts (9mm) imported joint-venture board, and the box is pasted with (10-15mm) shockproof and moisture-proof EVA damping material. The hardware accessories include: Butterfly lock catch, (straight) ball wrap angle, universal wheel with brake, wheel vortex, and handle. Scope of application: LED display screen, LED color screen, LCD display screen packaging and large export instrument transportation packaging and other fields. This aviation box meets the environmental requirements of European SGS! Welcome to inquire. Fireproof, waterproof, moisture-proof and shock proof, convenient for transportation.

Cosmetic Case

The Cosmetic Case is made of non-woven fabric or imported transparent acrylic plate and aluminum frame structure, and the Cosmetic Case cover is equipped with 1pcs exquisite handle, which is beautiful, practical and generous. The inner lining adopts aluminum movable support, which can be lifted and moved freely. The inner structure can be designed according to customer requirements.

packing box

The surface of the box is made of flame-retardant ABS material, aluminum frame structure or metal aluminum sheet, and the interior is made of shockproof material, which plays a shock absorption role and can effectively protect the products from damage. The inner shockproof materials include high-density shockproof EVA and shockproof pearl cotton with strong softness, which can be reasonably prepared according to different products of customers. Handle, pull rod and foot wheel can be installed for convenient transportation.

Handicraft Case

The Case surface is made of aluminum sheet or imported ABS or PVS, and its skeleton is specially developed aluminum profile, which is coated with wear-resistant and oxidation resistant, and looks generous and temperament. The surface of the box can be selected in different colors. Inside, non-woven fabrics of various styles and colors or imported EVA materials can be selected. The box style can be made of right angles or rounded corners.

Production requirements: each specification of luggage has two materials: alloy aluminum plate and special plastic plate, and a variety of colors for users to choose; The case lining material can be equipped with different fabrics, Interlinings of different colors and various high-quality sponges according to user requirements; According to the actual needs of users, the hard sponge lined in the box can also be processed and customized into various shapes to inlay the equipment and its accessories. Product features: high strength. The impact resistance of all kinds of bags is up to 100kg. After falling freely from a height of 4.5 meters at full load (after loading the instruments), the physical performance and measurement accuracy of the instruments in the box have no change. Superior moisture-proof performance, in the environment of more than 90% humidity for 48 hours, there is no abnormality in the box. The buffer is good. After a long time (30 days) of transportation in various ways and road conditions, the equipment in the box is normal and free of damage. It has strong carrying capacity. The carrying capacity of civil bags is more than 50kg, and that of industrial and national defense bags is more than 100kg (or customized boxes exceeding the standard).

Military Case

The main body of the Military Case chassis adopts high-quality aluminum copper alloy and aluminum zinc magnesium copper superhard aluminum alloy profiles, which have the characteristics of solid structure, beautiful appearance and good heat dissipation performance. They are widely used in military instruments, meters, electronics, communications, automation, precision machinery, etc.

Aluminum shell turnover box

Aluminum shell turnover box, also known as aluminum bag box, is widely used in machinery, automobile, home appliances, light industry, electronics and other industries. It is convenient to clean, convenient to turnover parts, neatly stacked, convenient to carry, and easy to manage.

Basic structure

A: plywood board: the competition is fierce. Some peers use materials that do not meet the design requirements in order to reduce the price of the box, such as 8mm instead of 9mm plywood, or even some worse plates (MDF, large core board). In this way, the plates will swell after the box is wet, so that they can no longer be used normally.

B: aluminum profile: aluminum is also divided into thickness. Aluminum is the framework of the box. The thickness not only determines the aesthetic appearance of the box, but also maintains the stability of the box when it is impacted by external forces. Aluminum materials must be processed by oxidation, because aluminum materials without oxidation process will be naturally oxidized and dull as long as they are placed for a period of time, which will directly affect the beauty of the box.

C: Hardware: the structure of hardware and the thickness of materials directly affect the use time of the box. Many manufacturers or users like to use plated hardware products, because they look beautiful for a short time, but in actual use, as long as the plated products are hit, the electroplated coating is easy to be damaged, and rust will occur after damage; Although the galvanized hardware products are ordinary in appearance, they can automatically release the decomposition protective layer and have strong damage prevention ability, so as to achieve good rust prevention effect.

D: shockproof layer: high density (EVA glue) and pearl cotton pasted in the box. The density, hardness and thickness of these two kinds of cotton determine the protection and shockproof degree of the loaded items; The three parameters must be moderate. Too high density and hardness will affect its shockproof effect; Too low, easy to sag, affecting service life.

E: the last and most critical accessory is the wheel. There are many kinds of wheels, including PVC wheel, PU wheel, truck wheel, etc. and according to other parameters of the wheel, such as single bearing, double bearing, single brake, double brake, steel thickening, the high and low temperature and weight that it can withstand; The price ranges from a few pieces to dozens of pieces. The quality of the wheels directly determines the normal transportation, placement and use time of the box.

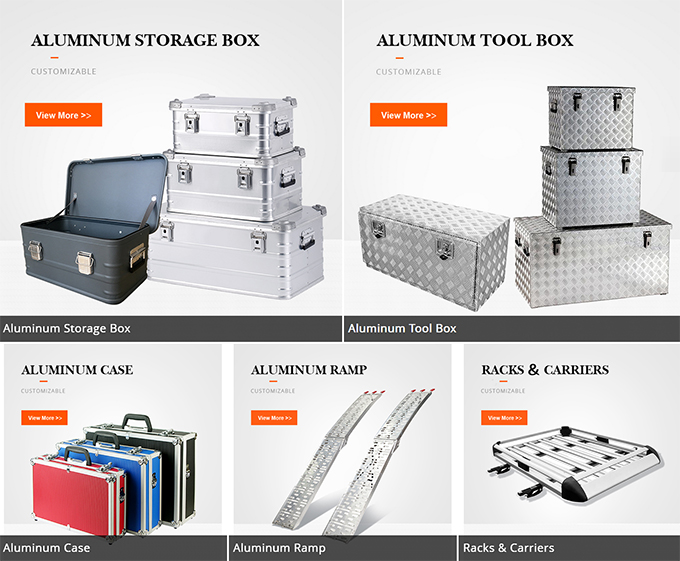

KASSICO, a leading aluminum products factory in Ningbo, China, Have 22 years' production experience in manufacturing custom aluminum storage boxes, truck tool boxes, aluminum tool case, aluminum ramp, car racks and carriers for outdoors, camping, overlanding, military, medical etc.

We supply full custom service, including developing OEM & ODM projects. Our company owns 15000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging.